Print and Sell

Sell 3D Printed Products. The Modern Way to Manufacture and Sell.

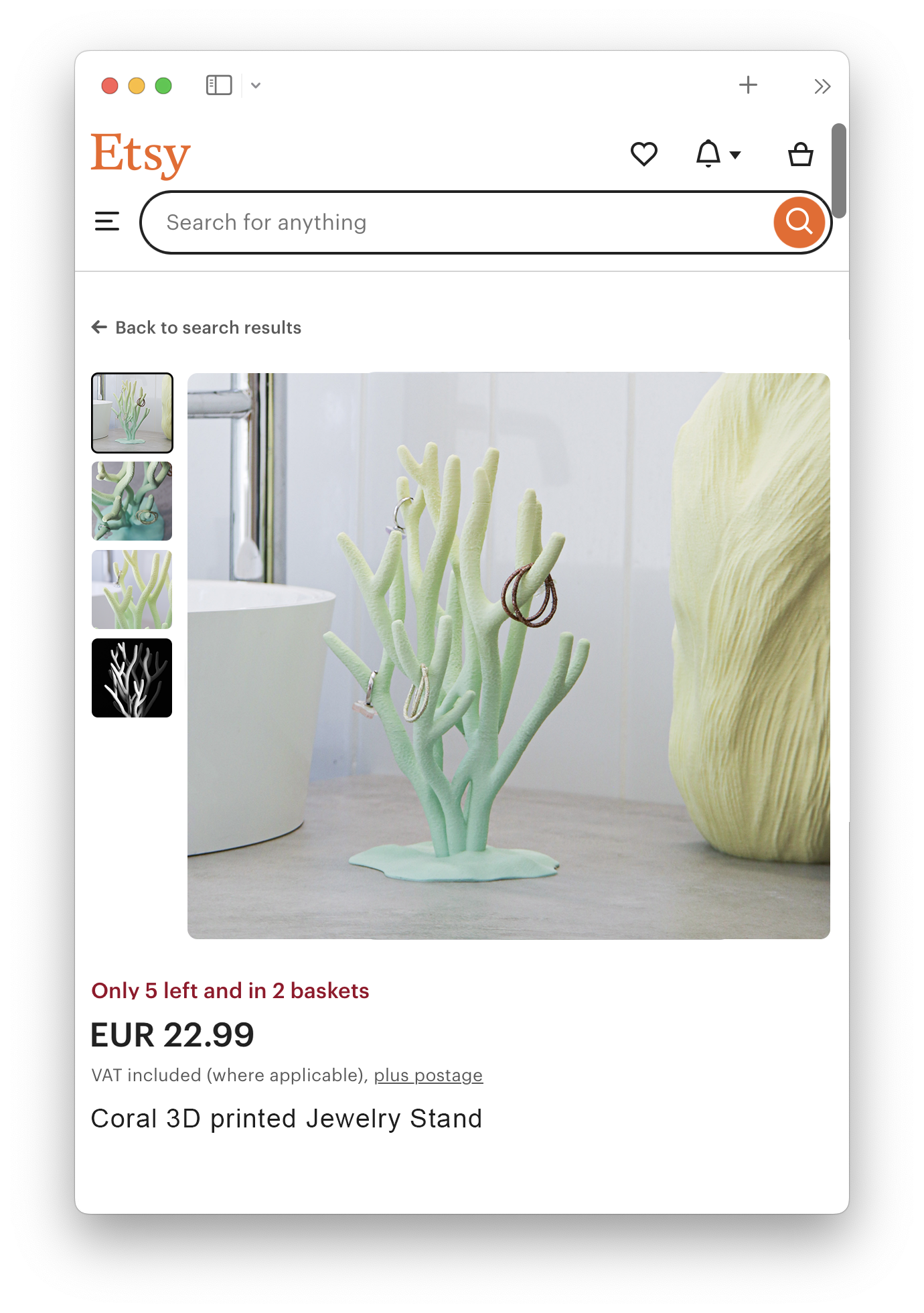

Join the future of manufacturing with revolutionary 3D printers. Purchase commercial licenses and gain access to catalogs of products ready for immediate production. You will receive 3D models with settings for most FFF printers, product images, and promotional files.

One-time commercial licenses with no royalty fees for your company, valid without limits for a lifetime. Simply add to cart.

How to obtain a commercial license:

1. Select the “Commercial License” option for the digital products you want to sell

2. Add it to your cart

3. Enter your company and store details, and register for access to additional materials

Frequently asked questions

Can I use photos and videos?

Yes, they are accessible through the business account.

Can I use the brand and author story?

Yes, you can share the story to help build trust and connect with your audience. It adds authenticity and strengthens the brand identity.

Can I add my own logo to the products?

Yes, since you are manufacturing the products, it makes sense to brand them with your own logo.

Can I list products on my website with a personal license and upgrade to a commercial license only after receiving an order?

No, this is not allowed. A commercial license must be purchased before publishing the products in your store or on social media.

Do I have to pay any sales fees?

No, all the earnings are entirely yours.